Quality Systems

Mantaline leverages its world-class quality systems, advanced material expertise, and manufacturing processes – refined through decades of experience in the automotive industry – to deliver exceptional engineered polymer solutions across all market segments.

Mantaline Certifications

Supplier Quality Assurance Manual

Mantaline Quality Systems and Equipment

- Laser-based non-contact profile continuous measurement

- Surface detection

- Tape placement detection

- Electronic SPC data collection

- Digital optical scanning for comparison to CAD drawings

- In-line cut length measurement system

- Product segregation system

- Recipe control system which sets extrusion parameters

- Part identification and traceability

These systems assure our customers that every part purchased from Mantaline conforms to their specification.

Quality is Built-in

Mantaline brings extensive expertise in rubber, silicone, and thermoplastic extrusion, molding, and finishing to a wide range of industries and applications. Our team has successfully addressed complex sealing challenges for customers in a diverse range of industries, including Automotive, Heavy Truck, Building & Construction, and general Industrial.

With a consultative approach, our hands-on applications, design, development, and manufacturing engineers’ partner with you at every stage. In-house tooling design and fabrication ensures precision and efficiency, integrating error-proofing and best practices directly into the process and final product.

Example of Mantaline’s commitment to Quality Assurance using automated profile measurement systems and surface flaw detection systems.

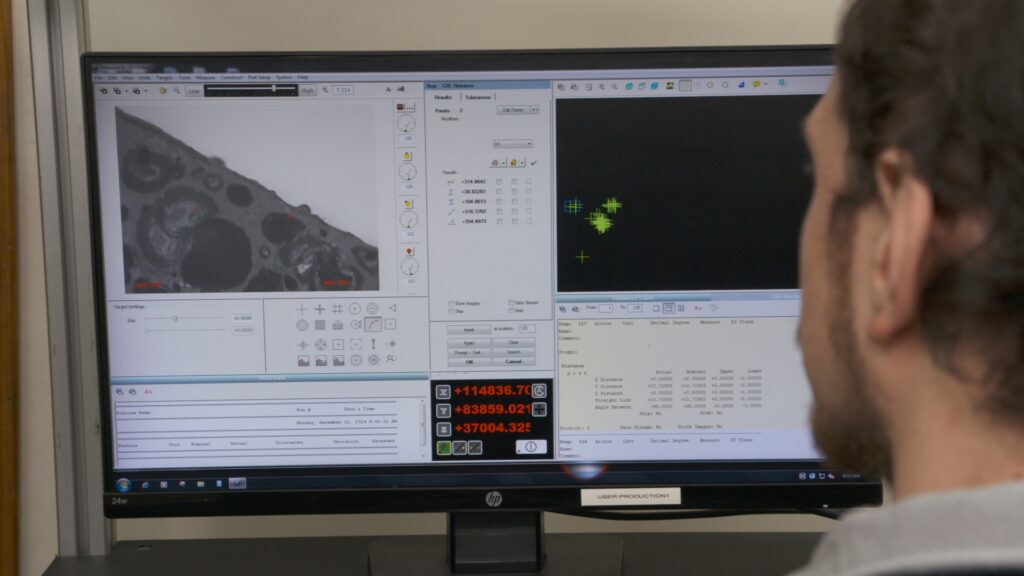

Another example of Mantaline’s investment in the latest scanning technology to compare the extruded part to the customer drawings.

Mantaline has invested in the latest automation technology to build-in Quality and to maximize labor efficiency to provide parts at a cost that represents value to our customer. This is the windowlace notching cell showing sensors/automation.

Mantaline has designed and implemented state-of-the-art Extrusion line control systems that allow us to analyze and understand the “Voice of the Process.”

Optical CMM – Mantaline uses the latest optical CMM (coordinate measurement machine) technology to measure film build of sprayed on coatings under high magnification