Automotive Market

At Mantaline, our seals are engineered to provide robust protection for automotive vehicles against environmental factors, while enhancing driver comfort through advanced noise, vibration, and harshness (NVH) control, and improving vehicle aesthetics.

Our team, equipped with a diverse array of technical skills and deep industry expertise, is prepared to address complex challenges in the automotive sector. We collaborate closely with customers to define precise goals and requirements.

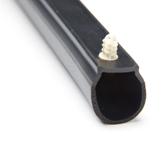

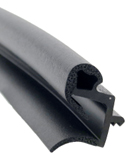

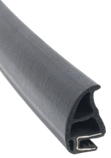

Mantaline specializes in the design, prototyping, validation, and manufacturing of high-performance sealing systems and components for a wide array of automotive applications. Our manufacturing capabilities include advanced extrusion, compression molding, injection molding, and secondary processes. By leveraging our materials expertise, Mantaline ensures the production of high-quality, reliable sealing solutions tailored to the specific needs of the automotive industry

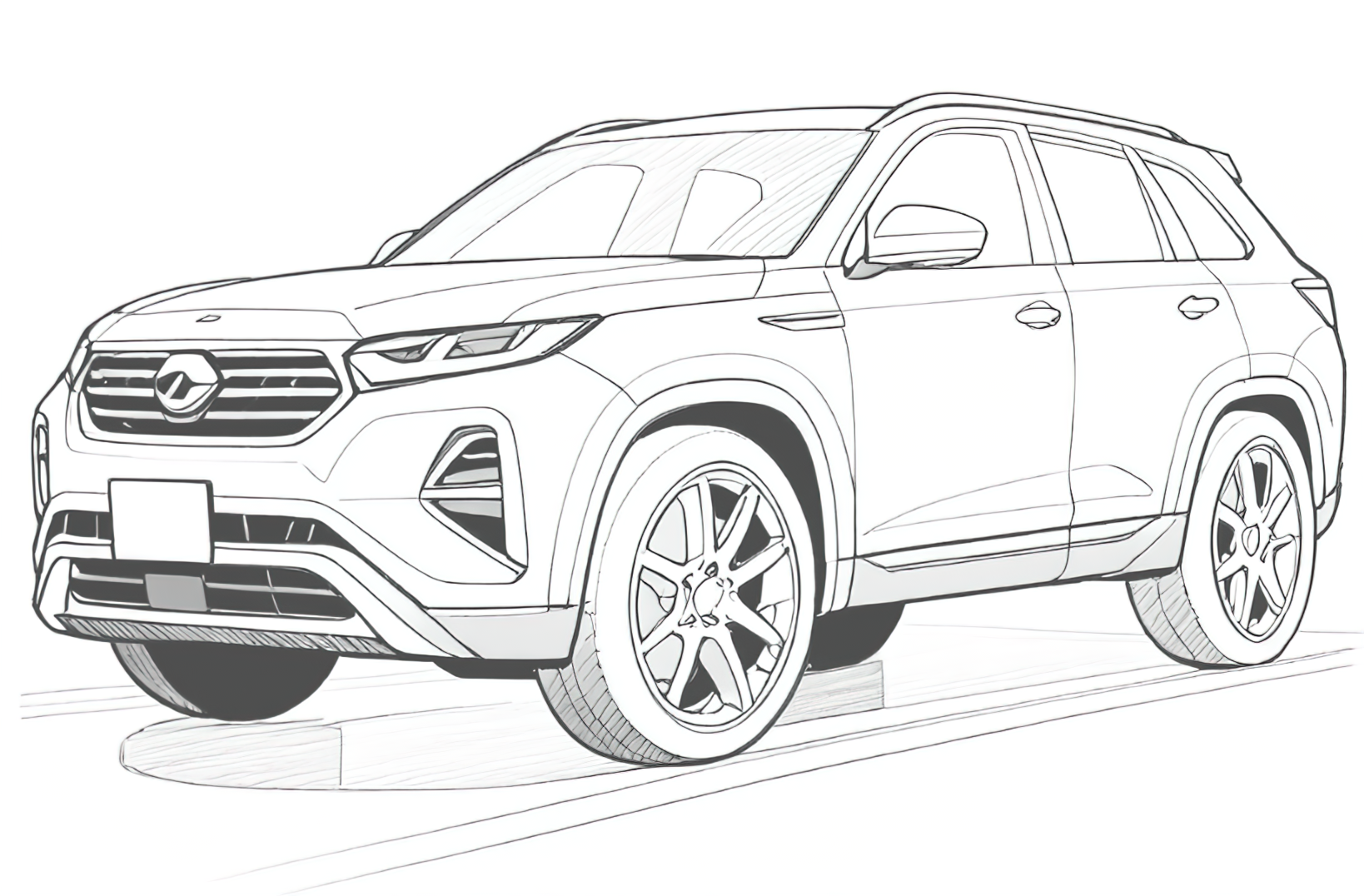

Hood Closeout

Hood to Cowl

Windshield & Backlite Molding

Sunroof

Roof Rail

Rear Spoiler

Pillar & Garnish Molding

Trunk Finisher & Closeout

Wheel Well Garnish

Rocker Panel & Sill

Beltline & Glass Run

Fascia Isolator & Spacer

Light Vehicle Applications

Exterior body – front-end module, fascia, spoiler, wheel arch, pillar trim, roof rail

Closures – hood/cowl, door, rocker panel, trunk/lift gate

Interior trim – dashboard, seat, seat track covers

Static and dynamic glass – windshield, backlite, sunroof, inner/outer belt, glass run

Under hood – engine cover, washer tubes

Fuel tank cushions

ID/OD cable protectors

NVH Isolators