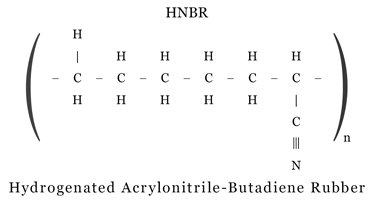

HNBR Rubber

HNBR (hydrogenated nitrile rubber) is a derivative of nitrile rubber that is hydrogenated in solution using precious metal catalysts. During this process the nitrile groups remain unchanged while the carbon-carbon double bonds in nitrile rubber convert into more stable single bonds.

HNBR (hydrogenated nitrile rubber) is a derivative of nitrile rubber that is hydrogenated in solution using precious metal catalysts. During this process the nitrile groups remain unchanged while the carbon-carbon double bonds in nitrile rubber convert into more stable single bonds.

Compression set resistance, good tear and tensile strength and abrasion resistance

Similar to other elastomers, HNBR rubber displays compression set resistance, good tear strength, good tensile strength, abrasion resistance and high elasticity. Along with these strengths HNBR rubber also has good heat aging resistance and low temperature tolerances compared to other heat- and oil-resistant elastomers.

With HNBR rubber, like nitrile, an increase in the acrylonitrile content increases resistance to heat and petroleum based oils and fuels, but decreases the low temperature performance.

Good viscoelastic properties, a wide service temperature range, resistance to strongly alkaline and aggressive fluids

With an array of beneficial properties, HNBR rubber continues to find it way into a broad range of applications, especially for the automotive industry. Other properties of HNBR rubber making it highly useful to the automotive industry include good viscoelasticity (property of materials that exhibit both viscous and elastic characteristics when undergoing deformation) when HNBR vulcanizates, a wide service temperature range, resistance to fluids of various chemical compositions and to strongly alkaline and aggressive fluids.

HNBR rubber exhibits a selection of good properties that usually are not found together in elastomers: heat aging resistance, oil resistance and low temperature flexibility. As the automotive industry requires improvements in performance and reliability, this combination of properties is pushing HNBR rubber to meet more of those requirements.

Used for automotive timing belts

Timing belts are the key automotive application employing HNBR rubber; a high stress and heat intensive component.