Capabilities

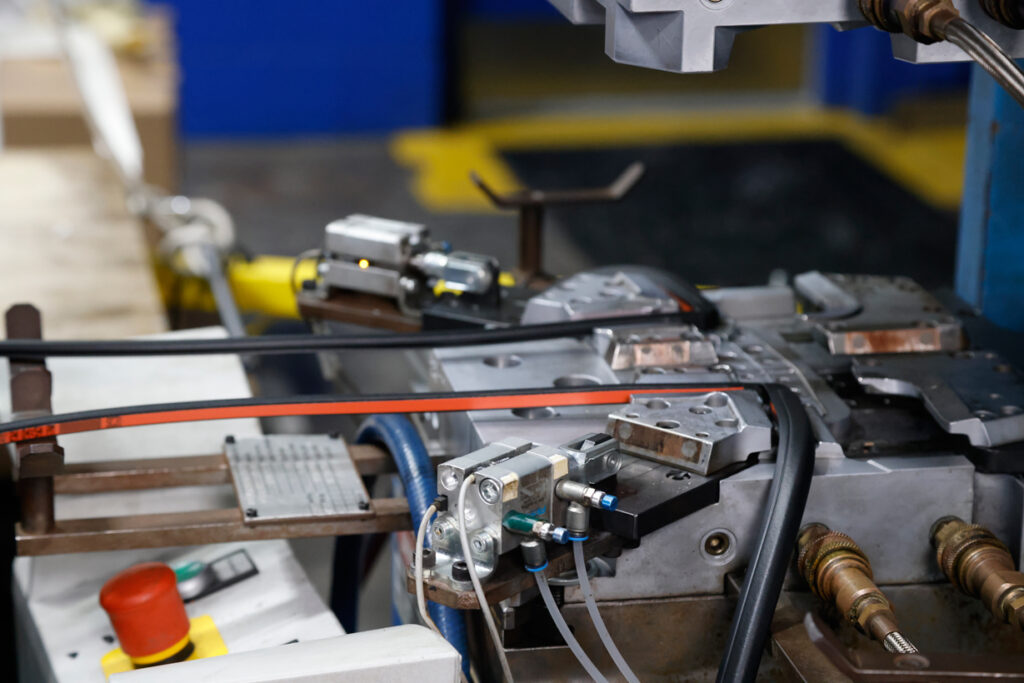

Mantaline’s world-class Operations range from application engineering, in-house tooling design and fabrication, and rapid prototyping to precision extrusion and injection molding manufacturing processes. With our broad expertise, we stay ahead of the competition by embracing innovation and continuous improvement through the implementation of automation and cutting-edge technology.

Extrusion Processes

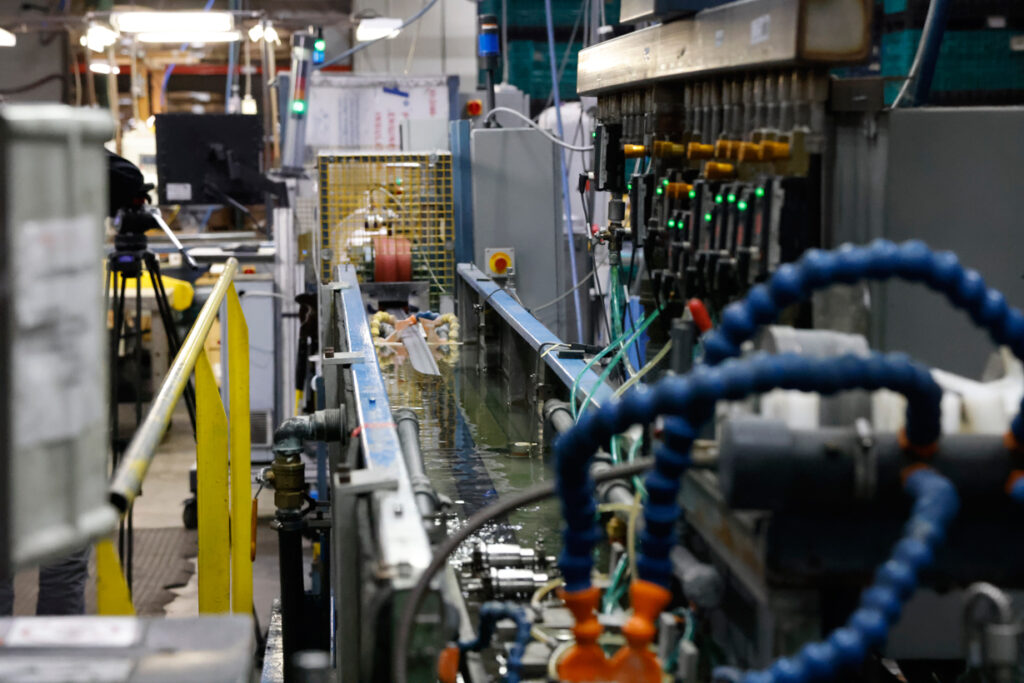

Mantaline has introduced best-in-class quality control to the extrusion process via in-line continuous measurement, surface quality detection, and product segregation systems that ensure the consistency and accuracy of every part we supply.

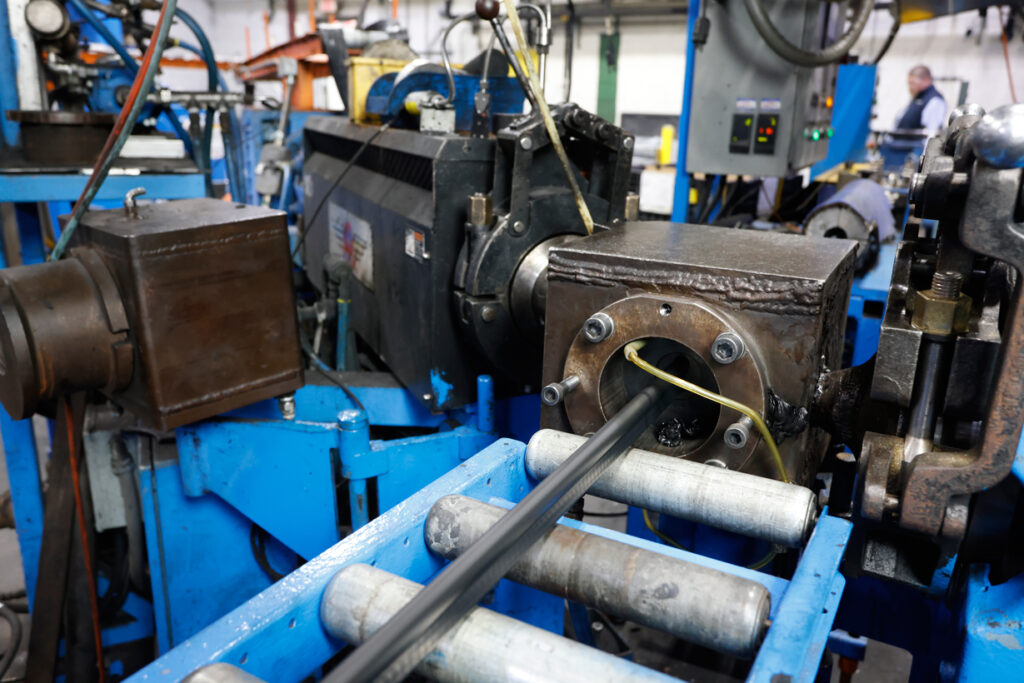

Rubber Extrusion

- Cure Systems – Microwave, Hot Air, and Salt

- Dual Durometer

- Metal and Wire Carrier

- Cord Inclusion

- Low friction surface coatings

- Graining and embossing

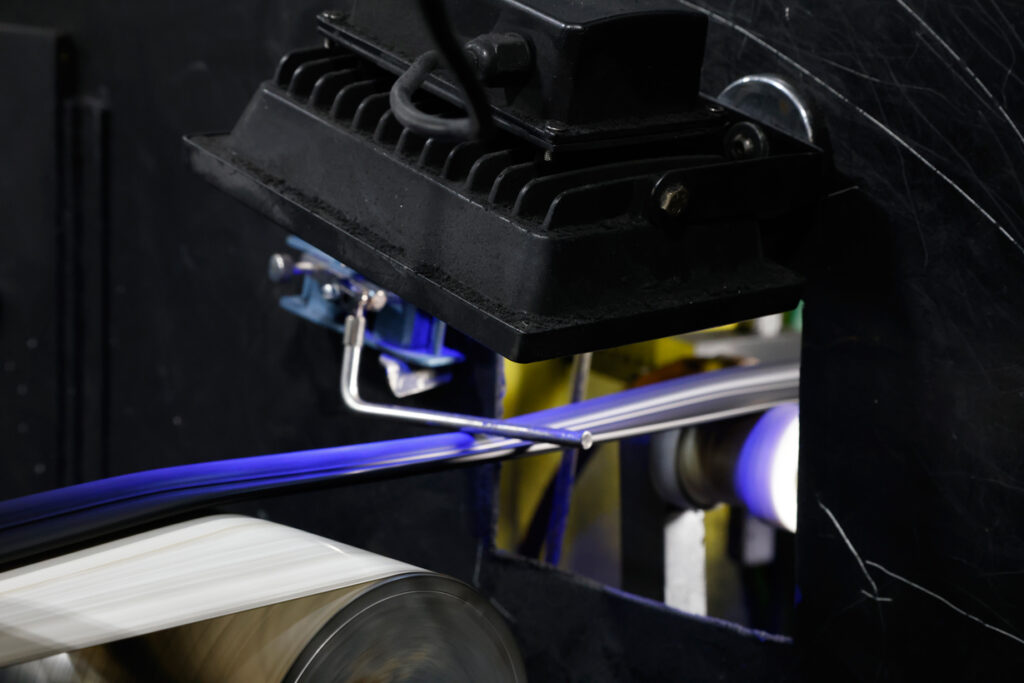

- In-line taping (heat-activated, pressure sensitive, and flocked)

Secondary Processes

- Automated cutting

- Notching and punching

- Drill & Pin insertion

- Off-line taping (Heat-activated or Pressure-sensitive)

- Low friction surface coatings

- Injection, compression, and transfer molding

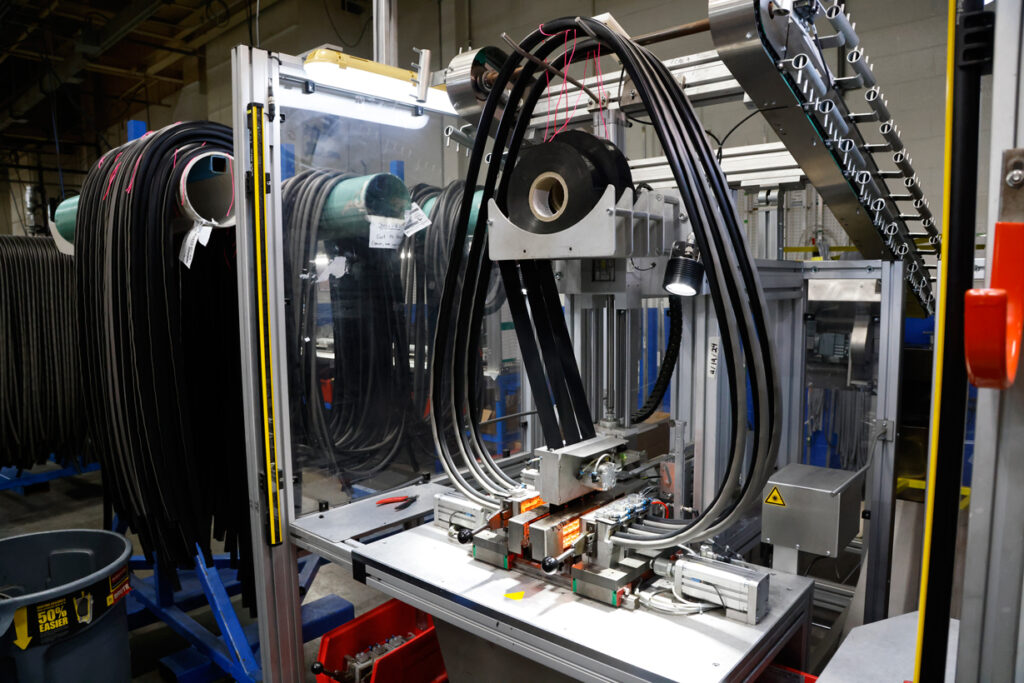

- Thin film splicing

- Heat welding

- Pneumatic splicing

- Robotic Coating and Adhesive Applications

Thermoplastic Extrusion

- Tri-extrusion

- Co-extrusion

- Metal and wire carrier

- Extruded low friction surface coatings

- Graining and embossing

- In-line taping (heat-activated, pressure sensitive, and flocked)

Molding Processes

- Rubber Injection Molding

- Plastic Injection Molding

- Rubber Compression Molding

In-House Tooling & Design

- Wire EDM

- CNC mill

- 3D printing

- Flow simulation

- Finite Element Analysis (FEA)

At Mantaline, we work with a wide range of elastomeric materials, including:

- EPDM Rubber: Known for its excellent resistance to heat, ozone, and weatherability.

- Nitrile, SBR & HNBR Rubber: Combines high strength with resistance to heat, oil, and chemicals. Offers superior resistance to oils and fuels.

- Neoprene Rubber: Provides good chemical stability and flexibility over a wide temperature range.

- Silicone: Ideal for high-temperature applications and offers excellent flexibility.

- Fluoroelastomer: Provides exceptional resistance to high temperatures and aggressive chemicals.

- Thermoplastics: Versatile materials that offer a balance of flexibility, durability, and ease of processing.

Mantaline’s sales and engineering staff will work with you to select the most appropriate and cost-effective material(s) and processes for your application.